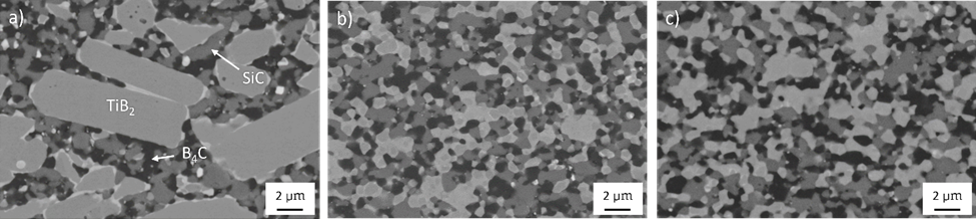

Impact of TiB2 source on the microstructure and properties of TiB2-SiC-B4C ceramics

S.M. Smith II, S. Filipovic, W.G. Fahrenholtz, G.E. Hilmas, C. Baldisserri, L. Silvestroni

submitted to the Journal of the American Ceramic Society.

Impact of TiB2 source on the microstructure and properties of TiB2-SiC-B4C ceramics

S.M. Smith II, S. Filipovic, W.G. Fahrenholtz, G.E. Hilmas, C. Baldisserri, L. Silvestroni

Abstract: The search for materials that meet the contemporary engineering challenges, including the Generation IV nuclear reactors and the ultra-high temperatures in hypersonic vehicles, requires the exploration of structures only found beyond those achieved through conventional synthesis and processing techniques. These far-from-equilibrium materials are achievable through the application of one or multiple extreme environments, allowing the systems to be kinetically trapped, or meta-equilibrated, in unique conditions across several length scales during processing. In this work, we provide an overview of how coupled extreme environments, such as high temperature, high load or shear, irradiation and oxidation, may lead to the formation of materials with unique hierarchical microstructures with tolerance to harsh conditions beyond the capabilities of conventional materials. We discuss fundamentals, challenges, and opportunities of unprecedented performances are here provided for metals, oxides, and boride ceramics highlighting the distinctive characteristics that make these far-from-equilibrium materials exceptional for use in fields where multiple extreme conditions are met, such as the aerospace, nuclear energy, and energy storage applications.

submitted to the Journal of the American Ceramic Society.

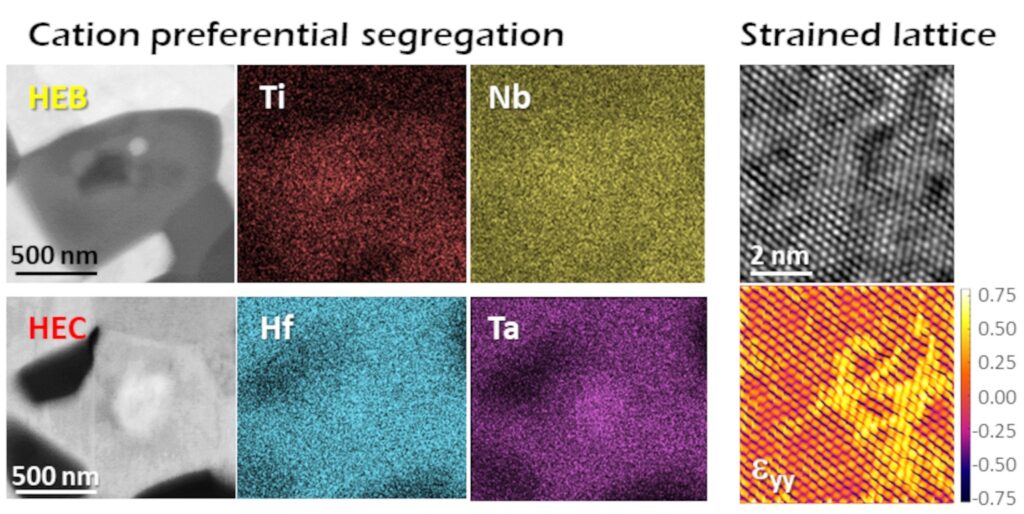

Dual ceramics based on multi-cation boride-carbide: TEM analyses and nanoindentation

S.M. Smith II, N. Gilli, W.G. Fahrenholtz, G.E. Hilmas, S. García-González, E. Jiménez-Piqué, S. Curtarolo, L. Silvestroni

submitted to the Journal of Materionics.

Dual ceramics based on multi-cation boride-carbide: TEM analyses and nanoindentation

S.M. Smith II, N. Gilli, W.G. Fahrenholtz, G.E. Hilmas, S. García-González, E. Jiménez-Piqué, S. Curtarolo, L. Silvestroni

Abstract: A dual phase boride and carbide ceramic with the nominal composition (Ti0.2Zr0.2Hf0.2Nb0.2Ta0.2)B2 and (Ti0.2Zr0.2Hf0.2Nb0.2Ta0.2)C was prepared by reactive synthesis and consolidated by spark plasma sintering. The resulting microstructure contained about 30 vol% boride and 70 vol% carbide. Compositional inhomogeneities were observed within single grains that had core-shell structures and preferential accumulation of specific metals in the boride or carbide phases. Specifically, Ti and Nb had higher concentrations in the boride, whereas Hf and Ta in the carbide. The Zr concentration was relatively equally distributed in the two phases. The dual phase ceramic had additional, distinctive features including nanosized inclusions, possibly related to local miscibility gaps and supersaturation, linear defects, and strain due to adjustment of the crystal structure. As a consequence, the fracture mode was transgranular with the crack path deviated by these nanometric microstructure alterations. Nanoindentation under 5 mN measured higher hardness and modulus for the boride, 30 and 525 GPa, as compared to the carbide phase, 22 and 425 GPa.

submitted to the Journal of Materionics.

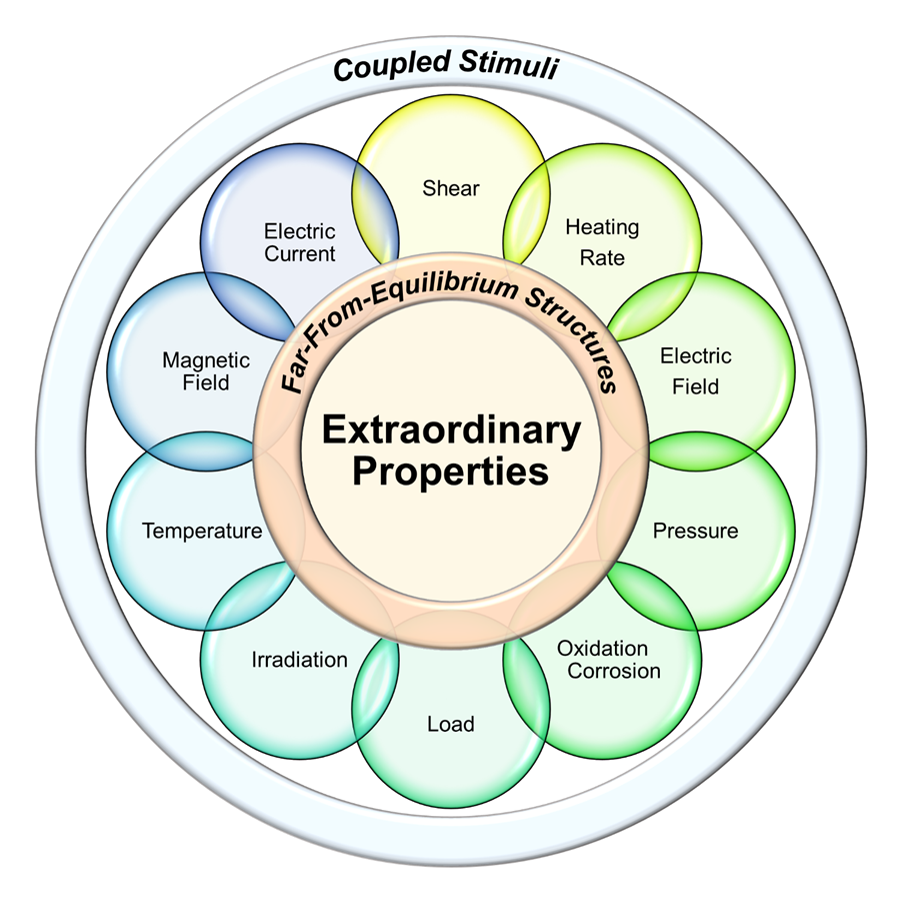

Synthesis of far-from-equilibrium materials for extreme environment

L. Silvestroni, L.M. Rueschhoff, K.A. Acord, R. Castro, C. Powell

MRS Bulletin 47, 1143–1153 (2022)

Synthesis of far-from-equilibrium materials for extreme environment

L. Silvestroni, L.M. Rueschhoff, K.A. Acord, R. Castro, C. Powell

Abstract: The search for materials that meet the contemporary engineering challenges, including the Generation IV nuclear reactors and the ultra-high temperatures in hypersonic vehicles, requires the exploration of structures only found beyond those achieved through conventional synthesis and processing techniques. These far-from-equilibrium materials are achievable through the application of one or multiple extreme environments, allowing the systems to be kinetically trapped, or meta-equilibrated, in unique conditions across several length scales during processing. In this work, we provide an overview of how coupled extreme environments, such as high temperature, high load or shear, irradiation and oxidation, may lead to the formation of materials with unique hierarchical microstructures with tolerance to harsh conditions beyond the capabilities of conventional materials. We discuss fundamentals, challenges, and opportunities of unprecedented performances are here provided for metals, oxides, and boride ceramics highlighting the distinctive characteristics that make these far-from-equilibrium materials exceptional for use in fields where multiple extreme conditions are met, such as the aerospace, nuclear energy, and energy storage applications.

MRS Bulletin 47, 1143–1153 (2022)

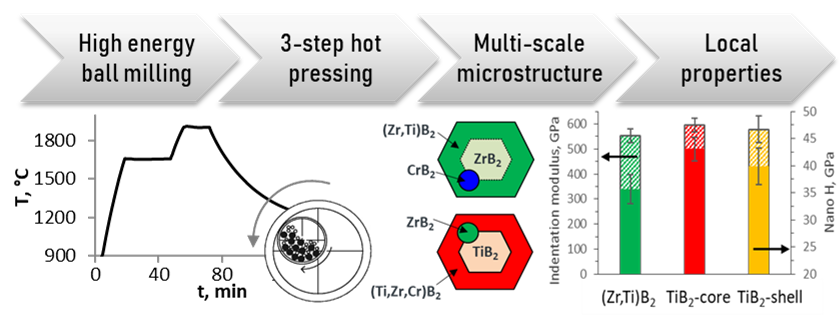

Multi-phase (Zr,Ti,Cr)B2 solid solutions: preparation, multi-scale microstructure and local properties”, Journal of Advanced Ceramics

L. Silvestroni*, N. Gilli, A. Sangiorgi, A. Corozzi, S. Filipovic, N. Obradović, L. Ortiz-Membrado, E. Jiménez-Piqué, W.G. Fahrenholtz

Journal of Advanced Ceramics 12(2), 414-431 (2023)

Multi-phase (Zr,Ti,Cr)B2 solid solutions: preparation, multi-scale microstructure and local properties”, Journal of Advanced Ceramics

L. Silvestroni*, N. Gilli, A. Sangiorgi, A. Corozzi, S. Filipovic, N. Obradović, L. Ortiz-Membrado, E. Jiménez-Piqué, W.G. Fahrenholtz

Abstract: Multi-phase ceramics based on ZrB2, TiB2 and doped with CrB2 and SiC were prepared by powder metallurgy and hot pressing to explore the possibility of obtaining multi-scale microstructures by super-saturation of complex (Zr,Ti,Cr)B2 solid solutions. Core-shell structures formed in TiB2 grains, whereas ZrB2 appeared to form a homogeneous solid solution with the other metals. Precipitation of nano-inclusions within both micron-sized borides was assessed by transmission electron microscopy and thermodynamics elucidated the preferential formation of boride inclusions due to the specific sintering atmosphere. In addition, atomic size factors explicated the precipitation of CrB2 nano particles into ZrB2-rich grains and of ZrB2 nano-particles into TiB2-rich grains. The hardness of the constituent phases measured by nanoindentation ranged from 36 to 43 GPa.

Journal of Advanced Ceramics 12(2), 414-431 (2023)

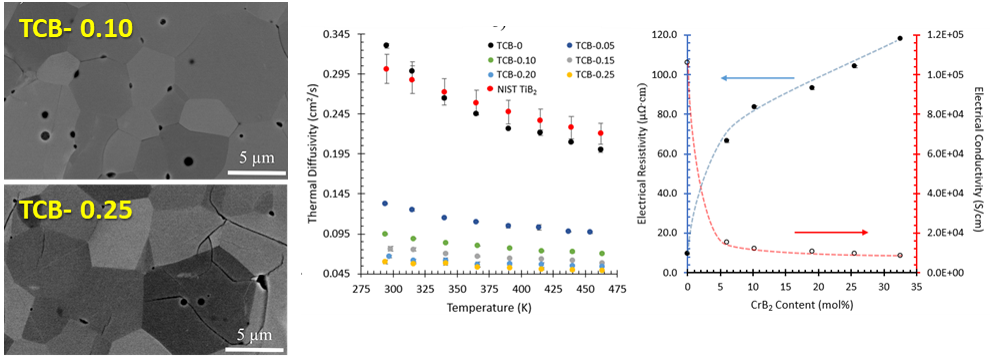

Thermal and Electrical Properties of Spark Plasma Sintered (Ti,Cr)B2 Ceramics

M. Smith II*, L. Feng, W.G. Fahrenholtz, G.E. Hilmas, L. Silvestroni

Journal of the American Ceramic Society 106(1), 632-638 (2023)

Thermal and Electrical Properties of Spark Plasma Sintered (Ti,Cr)B2 Ceramics

M. Smith II*, L. Feng, W.G. Fahrenholtz, G.E. Hilmas, L. Silvestroni

Abstract: Thermal and electrical properties were measured for TiB2 ceramics containing varying CrB2 contents up to 33 mol%. The room-temperature thermal diffusivity decreased with increasing Cr content from 0.330 ± 0.003 cm2/s for pure TiB2 to 0.060 ± 0.003 cm2/s for (Ti0.66Cr0.33)B2. The amount of anisotropy in the coefficients of thermal expansion increased with increasing Cr content and the c-axis had the greatest dependence on Cr addition, with an increase of more than 25% in the thermal expansion for 33 mol% CrB2 compared to TiB2, whereas the a-axis only increased by about 8%. The electrical conductivity was the lowest for (Ti0.66Cr0.33)B2 at ∼8.5 × 103 S/cm compared to ∼106.1 × 103 S/cm for nominally pure TiB2. Overall, the addition of CrB2 as a sintering aid for TiB2 was shown to have a significant effect on the thermal and electrical properties of TiB2 for additions as small as 5 mol% CrB2.

Journal of the American Ceramic Society 106(1), 632-638 (2023)

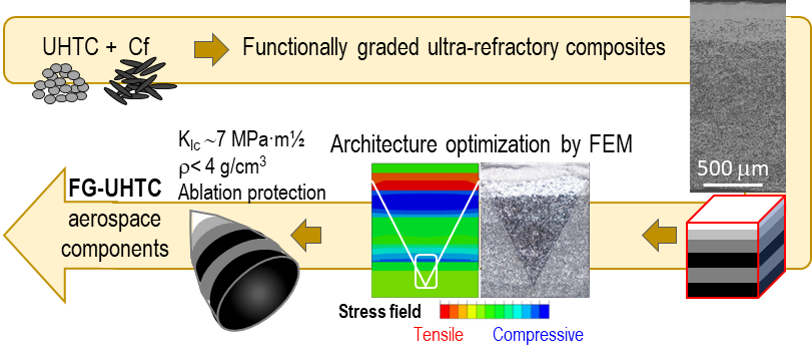

Functionally graded ultra-high temperature ceramics: from thermo-elastic numerical analysis to damage tolerant composites

L. Silvestroni, D. Pavan, C. Melandri, D. Sciti, N. Gilli, L. Ortiz-Membrado, E. Jiménez-Piqué, A.M. Grande

Materials & Design 224, 111379 (2022)

Functionally graded ultra-high temperature ceramics: from thermo-elastic numerical analysis to damage tolerant composites

L. Silvestroni, D. Pavan, C. Melandri, D. Sciti, N. Gilli, L. Ortiz-Membrado, E. Jiménez-Piqué, A.M. Grande

Abstract: To maximize the toughening contributions due to fiber bridging and residual stresses upon layering, ultra-high temperature ceramics containing variable amounts of short carbon fiber in functionally graded stacking sequences were designed and characterized. Stress fields evaluated by finite element model on (AB)nA and more complex asymmetric architectures were compared to the experimental fracture toughness pointing to an effective toughness increment in those structures where the notch fell in zones of residual compression. For the best composites, toughness at room temperature achieved 7 MPa·m0.5 and further increased to 10 MPa·m0.5 when tested at 1500°C within a light ZrB2-based composite with density below 4 g/cm3.

According to the numerical simulations and the effective microstructural features of the composites, the main guidelines for the realization of ceramics with simultaneous failure tolerance and ablation resistance were established.

Materials & Design 224, 111379 (2022)

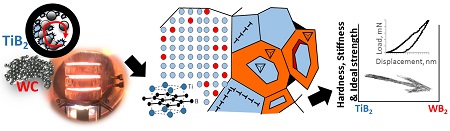

Disclosing small scale length properties in core-shell structured B4C-TiB2 composites

L. Silvestroni, S. Failla, N. Gilli, C. Melandri, U. Savacı, S. Turan, D. Sciti.

Materials & Design 197, 109204 (2021)

https://www.sciencedirect.com/science/article/pii/S0264127520307395

Disclosing small scale length properties in core-shell structured B4C-TiB2 composites

L. Silvestroni, S. Failla, N. Gilli, C. Melandri, U. Savacı, S. Turan, D. Sciti.

Abstract: This work explores the fine microstructural features of B4C-TiB2 composites and suggests an overall microstructure evolution from powder processing to sintering. In addition, small-scale grain structures are correlated to local properties measured by nanoindentation, thus providing trends in mechanical behavior. Dense ceramics were typified by development of a core/shell structure of the boride grains, with the shell comprising a (Ti,W)B2 solid solution with different assemblage and variable amount of W guest cation depending on the processing route. TEM analyses revealed chemical and morphological differences that were associated to the presumed densification mechanisms. Nanoindentation was used to extract the overall and single phase properties of TiB2 core, shell and B4C phase highlighting for the first time hardness and modulus variation as a function of the lattice perturbation, i.e. of nominally pure core boride and shells region. This work provides new experimental findings fundamental for the development and synthesis of high-performance structural materials starting from a small-length scale perspective.

Superhard single-phase (Ti,Cr)B2 ceramics

L. Feng, W.G. Fahrenholtz, G.E. Hilmas, L. Silvestroni

Journal of the American Ceramic Society 105[8], 5032-5038 (2022)

https://ceramics.onlinelibrary.wiley.com/doi/abs/10.1111/jace.18490

Superhard single-phase (Ti,Cr)B2 ceramics

L. Feng, W.G. Fahrenholtz, G.E. Hilmas, L. Silvestroni

“What is the point of being alive if you don’t at least try to do something remarkable?”

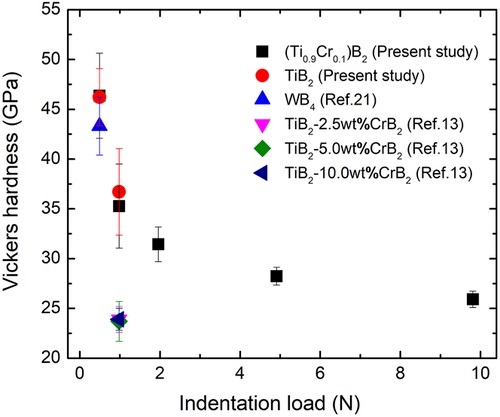

Abstract: A nominally pure and dense (Ti0.9Cr0.1)B2 ceramic was produced by spark plasma sintering of powders synthesized by boro/carbothermal reduction of oxides. The synthesized powders were a single phase and had an average particle of 0.4 ± 0.1 μm and an oxygen content of 1.2 wt%. Average Vickers hardness values of the resulting ceramics increased from 25.9 ± 0.8 GPa at a load of 9.81 N, to 46.3 ± 0.8 GPa at a load of 0.49 N. Compared to the nominally pure TiB2 ceramic obtained under the same processing conditions, the (Ti0.9Cr0.1)B2 ceramic had higher values under the same load due to the finer average grain size (2.4 ± 1.0 μm), higher relative density, and solid solution hardening. The results indicated that the Cr addition promoted densification, suppressed grain growth, and improved the hardness of TiB2 ceramics. This is the first report for dense and single-phase (Ti,Cr)B2 ceramics as superhard materials.

Journal of the American Ceramic Society 105[8], 5032-5038 (2022)

Design of ultra-high temperature ceramic nano-composites from multi-scale length microstructure approach

N. Gilli, J. Watts, W.G. Fahrenholtz, D. Sciti, L. Silvestroni

Composites Part B: Engineering 226, 109344 (2021)

https://www.sciencedirect.com/science/article/abs/pii/S1359836821007174

Design of ultra-high temperature ceramic nano-composites from multi-scale length microstructure approach

N. Gilli, J. Watts, W.G. Fahrenholtz, D. Sciti, L. Silvestroni

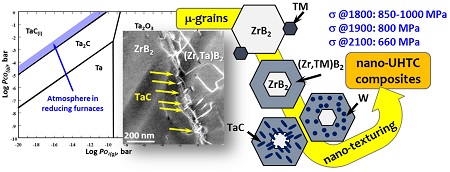

“What is the point of being alive if you don’t at least try to do something remarkable?”

Abstract: The evolution of the multi-scale microstructure of a (Zr,Ta)B2 solid solution was studied as a function of time and temperature. The ceramics were produced by hot pressing a mixture of ZrB2 with 15 vol% TaSi2 followed by annealing at 2100°C. Formation of a super-saturated solid solution led to the precipitation of TaC nano-needles within the micron-sized boride grain matrix. Phase stability diagrams were used to define the conditions of partial pressure within the sintering chamber that drove precipitation of nano-inclusions in the form of either metal or carbide. Through this approach, other systems containing various transition metals were explored to design other formulations for in-situ nano-composites with unprecedented strength at ultra-elevated temperatures.