Development of novel materials with reduced costs and improved mass efficiency of ballistic protection materials. Better performance and extended lifetime of hypersonic systems.

OBJECTIVES

SUSPENCE proposes innovative technological solutions to address the SPS Key Priorities that regard protection of personnel, critical assets and infrastructures by development of nano-structured super strong ceramics able to operate in harsh environments.

Harsh here defines two major fields:

- ballistic protection, where high strength, stiffness, and hardness with low weight is required to dissipate high energy impacts and resist penetration of the projectile into the body armor,

- hypersonic systems, which require materials able to survive to important heat fluxes as well as aerodynamic and mechanical loads.

Bottlenecks

Current available materials suffer of a series of technological limitations, like not favorable performance and production cost to weight ratios or inability to perform under hot ablative fluxes.

Our solution

Ultra-high temperature ceramics (UHTCs) are possible candidates that, upon suitable composition and microstructure tailoring, can offer a solution to both ballistic and hypersonic areas. Among them, Titanium diboride (TiB2) can merge the weight, hardness, strength and hot erosion requirements.

Novel TiB2-based ceramics will provide a valuable alternative to existing armor materials based on alumina by significant weight reduction and improved mechanical properties. Further, compared to boron carbide-based ceramics, TiB2-based ceramics offer significant reductions in processing and machining costs without sacrificing mechanical properties or high ballistic efficiency.

On the other hand, the use of TiB2-based systems will be a lower density solution compared to the more popular and heavier ZrB2 and HfB2 based ceramics to protect components working in extremely high temperatures from heat and corrosion damages while also preserving their functionality.

SUSPENCE will develop novel materials with reduced costs and improved mass efficiency of ballistic protection materials and also extend the performance and lifetime of hypersonic systems.

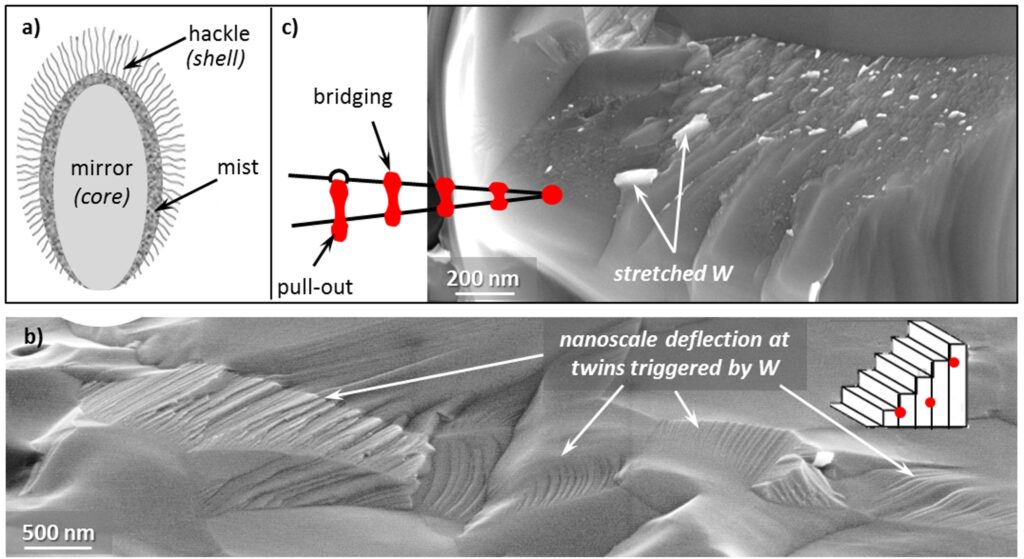

This will be accomplished by merging TiB2 with a secondary very hard phase and a transition metal (TM) compound to exploit the multiple benefits of the single phases. Key to the achievement of high strengths from room temperature and up to at least 2000°C, is the development of a particular morphology, called core-shell. This comprises a core with the nominally pure diboride grain seed, i.e. TiB2, and a solid solution shell that contains variable amounts of a second TM cation, i.e. (Ti,TM)B2. By adequate sintering and post-densification thermal treatments, we will promote development of the shell into a hierarchical UHTC-TM nano-composite consisting of homogeneously distributed nano-sized metallic inclusions embedded in micron-sized ceramic grains that will offer benefits by increase of local fracture toughness and strength, significant plastic deformation and ability to support high loads in the ultra-high temperature regime and enhanced oxidation behaviour.

The developed and optimized compositions will be then tested in relevant conditions for each application.